TURBO COUPLING – HYDRAULIC COUPLING

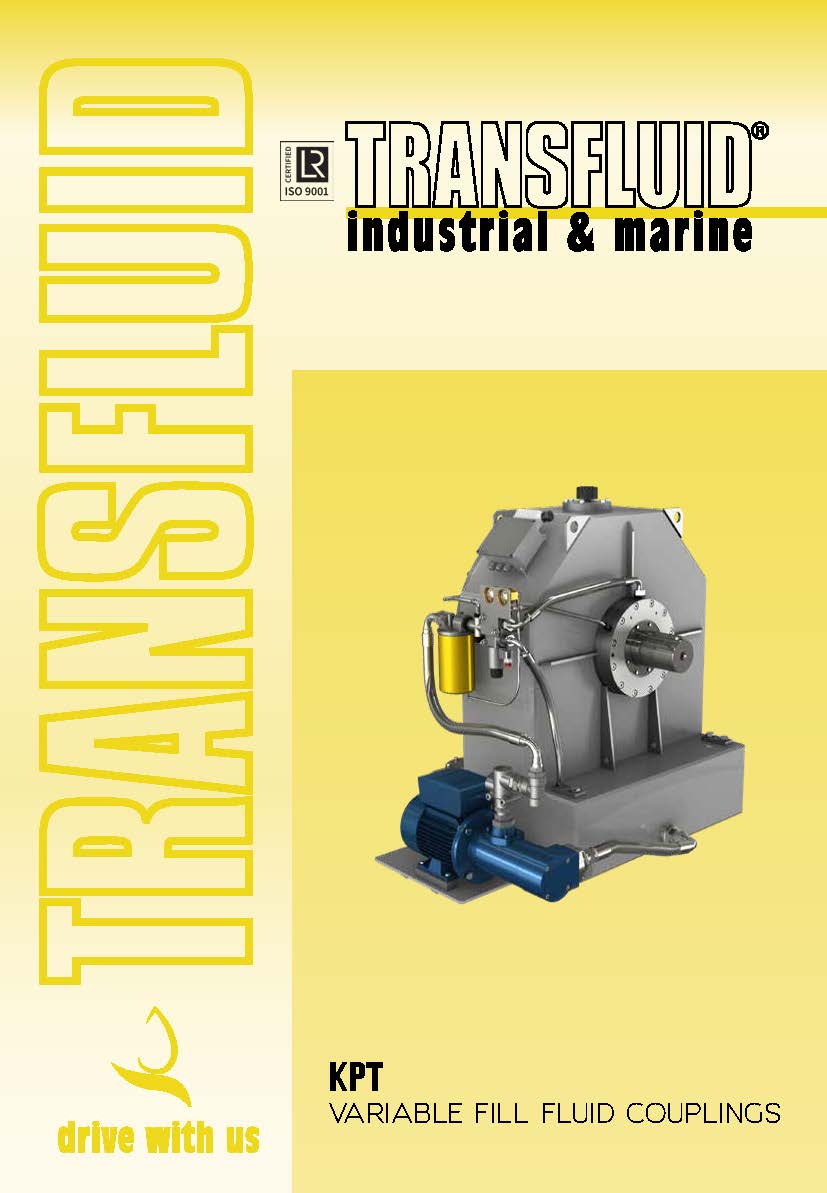

The KPTB is a variable fill fluid coupling designed to be a start-up drive or variable speed drive.

The KPTB hydraulic coupling has an externally driven oil feeding pump and a remote electrically operated ON-OFF valve. When the valve is turned ON the fluid coupling circuit is fed, when it is turned OFF rapid oil drain occurs through orifices located on the periphery of the coupling. The forced bearing lubrication is continuously assured.

The oil pump flow can be operated through an oil flow control valve or frequency converter (integrated into the oil feed pump motor), allowing KPTB to be a variable speed drive.

The KPTB range is suitable for power up to 1700 kW as start-up drive and 500 kW as variable speed drive.

The input and output straight shafts can be connected to an electric motor and driven machine by elastic and flexible couplings.

Standard accessories include: oil motor pump, oil filter with pressure and temperature gauges, ON-OFF electric valve, oil temperature switch, oil level indicators, connecting wiring box with plug.

Options include: water or air heat exchanger, quick release valves, output pulley, flexible and elastic couplings, cardan shafts and electric control board.

Special versions for low-temperature operation and Eex design are available.

HYDRAULIC COUPLING – FEATURES

The variable fill fluid coupling allows a disconnect of the motor from the load granting the following advantages:

- motor start-up at no load

- smooth start-up even possible under nominal motor current by full starting control

- shock and overload protection

- absorbtion of vibrations

- high radial load capacity (KPTE)

- no belt slip

- remote control by electric valve

- load positioning

- cheap and easy maintenance due to external mounting of main accessories like oil filter, feeding pump and control valve

- longer life thanks to no friction linings to wear out

- accurate variable speed performances

VARIABLE FILL FLUID COUPLINGS – APPLICATIONS

Start-up drive:

– mills, crushers, wood chippers, grinders, shredders

– belt conveyors

– reciprocating and centrifugal pumps, compressors

– marine propulsion

– generators

– centrifuges, fans and blowers

– mixers

Variable speed drive:

– centrifugal pumps and compressors

– fans and blowers

– belt conveyors

HYDRAULIC COUPLING: ACCESSORIES

MPCB MANAGEMENT SYSTEM

The MPCB for KPTB and KSL, is an electronic device, designed and manufactured by Transfluid, with Transfluid’s proprietary software, capable of performing the following functions:

- Monitoring of input and output fluid coupling speed

- Monitoring of all fluid coupling parameters

- Sending fc status and alarm signals to the main control room

- Implementation of interlock logics

- Local or remote output speed control

TRANSFLUID S.p.A. – Cap. Soc. EUR 520'000 – C.F./P.IVA 00790770150 – R.E.A. VA 0310612 – N. Mecc. VA 059280 – VAT NUMBER IT 00790770150

TRANSFLUID S.p.A. – Cap. Soc. EUR 520'000 – C.F./P.IVA 00790770150 – R.E.A. VA 0310612 – N. Mecc. VA 059280 – VAT NUMBER IT 00790770150