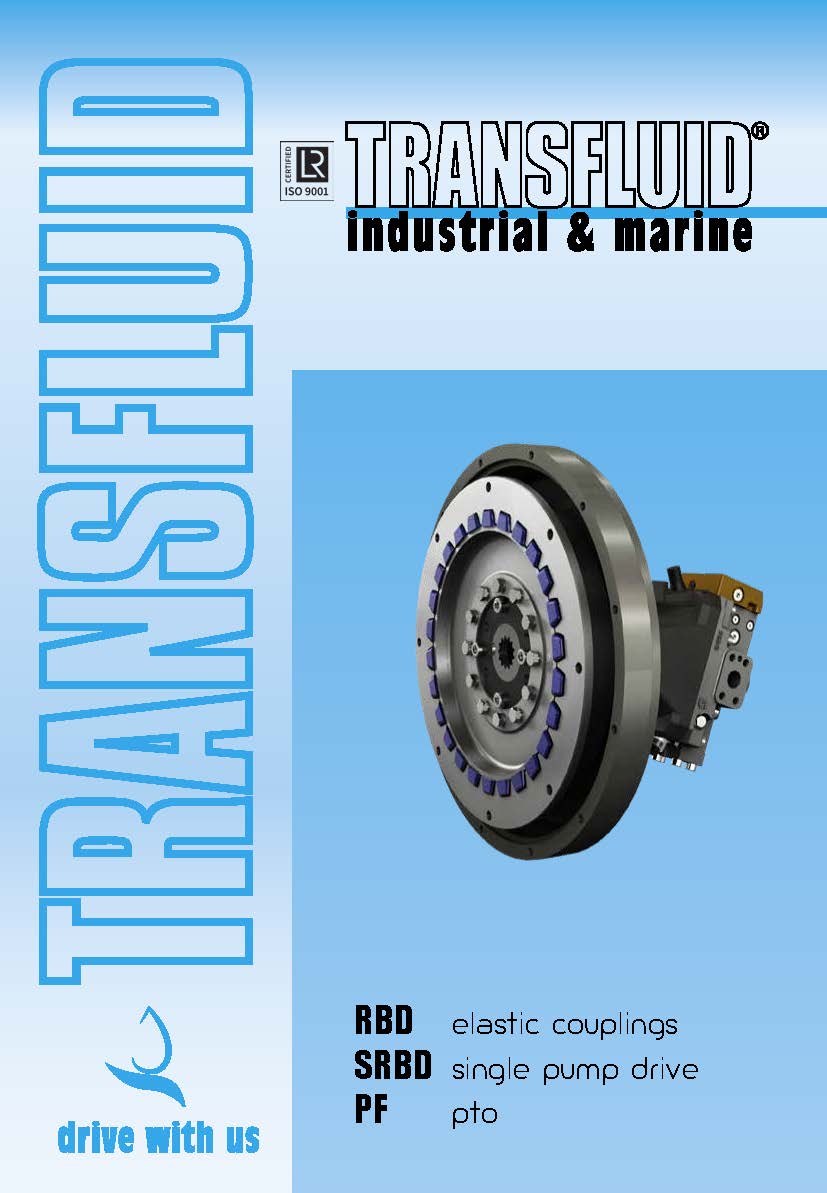

RUBBER COUPLING – SHAFT COUPLING

The RBD drives are designed for industrial engines in stationary applications such as generators, pumps and compressor sets. Mobile applications include forklift trucks and earth-moving equipment.

RBD elastic couplings have many advantages:

ease of assembly, weight and size, small axial profile and competitive price. Drives are also supplied with standard SAE flanges for ease of installation.

These rubber couplings are also available in the SRBD version: the RBD complete with SAE or DIN 5480 finished hubs and selected SAE flanges to facilitate a complete solution at a competitive price.

Atex certification is available too.

CONFIGURATION OF RBD ELASTIC COUPLINGS

Couplings can be provided:

- with or without hub

- with spline or keyway

- with conical locking coupling

- with housing for hydrostatic drives

TECHNICAL CONSTRUCTION OF TRANSFLUID’S SHAFT COUPLINGS

The drive principle uses internal and external teeth; the only difference is that the external teeth are blocks of special rubber molded compounds.

The external ring, in aluminum, has a profile corresponding to the rubber molded compound and can be directly mounted on the output flange of the prime mover.

By this method it is also possible to absorb small angular and radial misalignments.

TRANSFLUID S.p.A. – Cap. Soc. EUR 520'000 – C.F./P.IVA 00790770150 – R.E.A. VA 0310612 – N. Mecc. VA 059280 – VAT NUMBER IT 00790770150

TRANSFLUID S.p.A. – Cap. Soc. EUR 520'000 – C.F./P.IVA 00790770150 – R.E.A. VA 0310612 – N. Mecc. VA 059280 – VAT NUMBER IT 00790770150